From architectural prototypes and industrial components to art installations and furniture, MAGNUM’s large-scale 3D printing capabilities are reshaping industries and pushing the boundaries of what can be achieved with additive manufacturing.

Price available on request (info@dream3d.co.uk)

Please scroll down to find full product specs, features, videos and more 👇

Product Details

Pictures & Videos

Buying Options

Product details

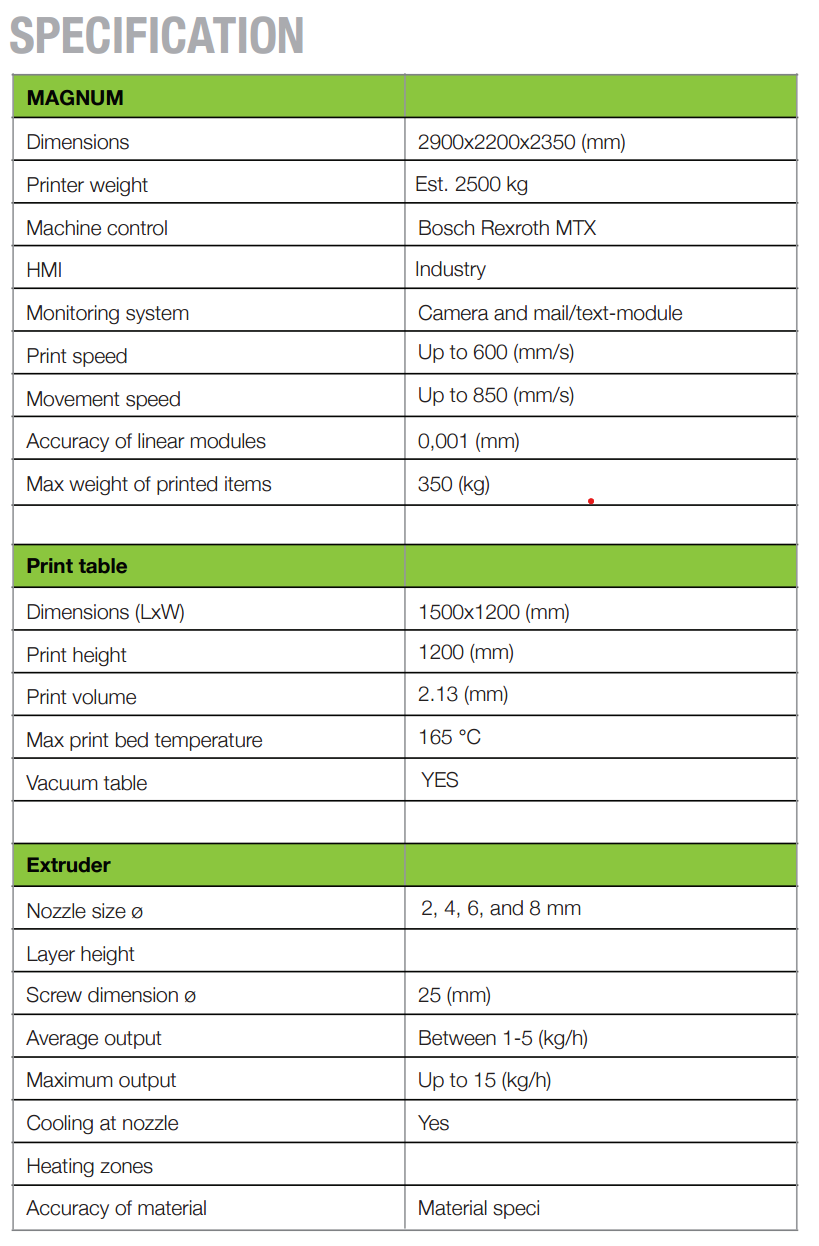

Magnum boasts a high printing speed and a high accuracy -perfect for 3D printing large objects extremely accurately while minimizing the possibility of warping. Magnum embraces innovation in any way possible as the state-of-the-art product for high volume 3D printing.

From architectural prototypes and industrial components to art installations and furniture, MAGNUM’s large-scale 3D printing capabilities are reshaping industries and pushing the boundaries of what can be achieved with additive manufacturing. By combining recycled thermoplastics, large volume, and the 3D-printing technique, MAGNUM enables you to turn waste into value. The manufacturing method of the future is here.

The Magnum system leverages a sophisticated cloud-based operating platform, enabling a flexible, agile feature set. Several types of functionality, including the patented heated vacuum table and proprietary slicing technology, bring breakthrough features to the platform.

By utilising a granules/pellets-based open material system, MAGNUM enables significant cost savings compared to traditional 3D printing technologies that rely on proprietary filament. Moreover, the printer’s speed and productivity contribute to cost efficiency by reducing production time, streamlining workflows, and optimising resource utilisation.

With its advanced technology and large build volume, MAGNUM can produce a substantial number of objects or components in a significantly shorter time frame, maximising productivity and efficiency, Ideal for industries that require rapid production.

The Magnum attempts to not only make 3d printing easy, but it also wants the whole process for you as a customer to be easy. Fast and easy installation and a short time to start printing!

The 3D print extruder is a key component in Material Extrusion. It is responsible for melting and precisely depositing the material onto the build platform to create a 3D object layer by layer.

Magnum’s extruder is controlled by advanced firmware, moving the filament from the spool to the melt chamber, where it is heated and extruded through the nozzle onto the build platform. By meticoiusly controlling the flow and consistency of the material, MAGNUM is capable of producing accurate and detailed 3D prints.

Fast turnaround with large print volume – Magnum’s robust feature set and patented technology allows for fast iteration and testing of new large-size products. Print speed, build volume, and output quality level make Magnum an excellent choice for product design, architecture, and engineering industries.

The MAGNUM’s origin in Sweden signifies a high standard of production, engineering excellence, and quality assurance

A wide range of materials and open source filaments is accepted. Using granules/pellets instead of filament has many advantages when you want to print large. Allows higher output, and It can sometimes be as much as ten times cheaper than equivalent filament.

MAGNUM offers an extensive range of pellet based materials that can be effectively printed, providing versatility and flexibility for various applications. Our 3D printer was specifically crafted to work with Plastics, Recycled materials, Biomaterials, Composite materials, Recycled rubber and Custom Formulations – everything that is Polymer based.

Pellets, also known as Fused Filament Fabrication (FFF), is a type of 3D printing technology that uses plastic pellets as the primary material. One of the advantages of pellets 3D printing is the wide availability of materials, such as ABS, PLA, nylon, TPU and more. Also, pellets are inexpensive compared to filaments and other materials, making them accessible to a wide range of users.

Magnum is specifically designed to leverage recycled granules as printing material to maintain a sustainable manufacturing process. The granules are fed into a heated extruder, where they are melted and precisely deposited onto a build platform to create a 3D object layer by layer.

Use granules, pellets, recycled materials, or open-source products to leverage Magnum’s flexible material system. Examples de PETG, rPP, rTPE and rPA.

• Sufficient free space in front (minimum 2m) and at the back

(minimum 1m) of the machine.

• Basic ventilation must be provided.

• Maintain room temperature above 10°C.

Buying Options

Debit/Credit Card (VISA/MASTERCARD/MAESTRO/AMERICAN EXPRESS)

Business Account Credit Terms – between 30-60 days – Please email us at Orders@Dream3D.co.uk

PayPal

Klarna

stripe

Bank Transfer – Please email us at Orders@Dream3D.co.uk

Business Finance Lease – Please email us at Orders@Dream3D.co.uk to find out more

Other recommended products

£5.39 Original price was: £5.39.£5.01Current price is: £5.01. (excl. VAT)

£311.69 Original price was: £311.69.£296.11Current price is: £296.11. (excl. VAT)

£44.96 Original price was: £44.96.£42.71Current price is: £42.71. (excl. VAT)

£65.33 Original price was: £65.33.£62.06Current price is: £62.06. (excl. VAT)

£44.34 Original price was: £44.34.£42.12Current price is: £42.12. (excl. VAT)

You might also like

£8,300.00 Original price was: £8,300.00.£8,100.00Current price is: £8,100.00. (excl. VAT)

£3,635.00 Original price was: £3,635.00.£3,600.00Current price is: £3,600.00. (excl. VAT)

£500.00 Original price was: £500.00.£485.00Current price is: £485.00. (excl. VAT)

£11,765.00 Original price was: £11,765.00.£11,700.00Current price is: £11,700.00. (excl. VAT)

£2,000.00 Original price was: £2,000.00.£1,660.00Current price is: £1,660.00. (excl. VAT)

Specialist retailer of 3D Printers, 3D Scanners and 3D Software since 2013

My Account

We accept

Categories

CUSTOMER REVIEWS

© Copyright - Dream 3D Ltd | Cookie Policy | Privacy Policy | Price Match Promise | Refunds/Returns/Cancellations Policy

Contact us for a quote